Food Safety Hazards Considerations for Plant-Based Meat Alternatives

The shift in consumer appetite to plant-based proteins, or meat alternatives, continues to grow in popularity as an alternative to animal-based proteins. The reasons for doing so range from meeting personal health goals (i.e., cholesterol reduction), ensuring humane treatment for animals, reducing the impact of global warming to meeting food supply requirements for an ever-increasing world population.

Even with increasing consumer adoption and grocery stores dedicating more and more shelf space to this new category of products, knowledge of potential food safety hazards still remains limited. Even so, companies take specific steps to reduce the likelihood of food safety issues within the manufacturing facility by working with food safety experts.

The Hazards We Know

Biological Hazards

Consumers often associate biological hazards with animal-based proteins when it comes to consumer-prepackaged foods.

Unlike typical meat products that generally consists of one or few ingredients, plant-based protein products are formulated with many ingredients as well other additives to simulate the taste, texture, appearance, and mouthfeel of conventional meat products. These ingredients can naturally contain or be introduced through external factors or processing create their own unique type of food safety risks.

For example, cooked plant protein sources such as grains and legumes can cause food poisoning if the proper cooking and cooling procedures are not followed during manufacturing. If pathogenic bacteria, viruses, and parasites are not eliminated through sufficient cooking temperatures, bacteria may proliferate and potentially generate toxins if cooling-after-cooking time/temperature exceeds the acceptable level.

Chemical Hazards

Chemical hazards in plant-based proteins can also pose food safety risks. They can be categorized as follows:

- Dried vegetables and fruits are one known sources of mycotoxins. The human body can process and dispose of these chemicals when consumed below a certain threshold through food. Increasing the proportion of dried plant ingredients in food can increase chances of mycotoxins to go above acceptable levels and make the food product unsafe.

- Pesticides are used to manage the insects and rodents. Usage is strictly monitored to ensure they do exceed pre-determined thresholds for food product safety. However, since various plant types require different thresholds of pesticides, the higher the number of plant-based ingredients in the food product, the greater the probability that pesticides will exceed the safe level.

- Heavy metals, such as lead, mercury, arsenic, and cadmium are known to be unsafe if consumed above certain amount in food. Some vegetables, fruits and grains naturally contain certain heavy metals such as rice, which a well-known source for arsenic. Heavy metals can also be introduced into fruits and vegetables during the growing stage for instance such as through the water that used and containing high levels.

- Natural toxins in some fresh fruits and vegetables are also other known examples of chemical hazards. Examples include cyanide in apricot kernels, cassava root and bamboo shoots; hypoglycin in unripe ackee fruit; and solanine and chaconine in potatoes.

Aside from the well-known physical hazards such as glass, wood, stone, and metal sometimes making their way into food products, plant-based products are commonly susceptible to additional ones such as pieces of fruits stones or plant stems.

Unknown Hazards

During product development, ingredients serve as the reference for predicting the characteristics of the finished product. This approach applies to any type of product. Unfortunately, the true characteristics and potential hazards of the finished product is not fully known until the manufacturing stage at which time can sometimes produce unexpected results. To address this, a trial run is typically performed to verify the accuracy of what was originally predicted or intended in the product development lab against actual manufacturing results.

These results from a trial run can either be positive, negative or combination thereof. The manufacturer however must be aware of potential negative outcomes in advance to be able to evaluate the finished products against the defined acceptable criteria. The very same holds true when it comes to manufacturing the novel foods with plant-based proteins. The following offers two such examples of multitude of uncertainties:

- Extrusion process: Extrusion is one of the most commonly used food manufacturing processes and enables the production of a diverse range of food products. For simulated meat products for example, extrusion is applied at a high temperature (i.e. above 100 Celsius; thermal energy and high pressure (i.e. mechanical energy) to convert plant-based ingredients into to a desired texture and form. Even though high temperatures can reduce the microbial load in the food, the application of extreme temperatures and mechanical energy may inadvertently generate unwanted chemical residues or alter the quality of the protein. However, there are still not sufficient scientific evidence in this regard.

- Pea protein allergy: There have been incidents that pea proteins used in highly processed meat substitutes have triggered peanut allergies in some people. This can perhaps be attributed to a chemical structure change that takes place within the pea protein during processing such as through extrusion. Further scientific case studies are required as pea protein may have a different allergic risk than regular pea to which some individuals are allergic.

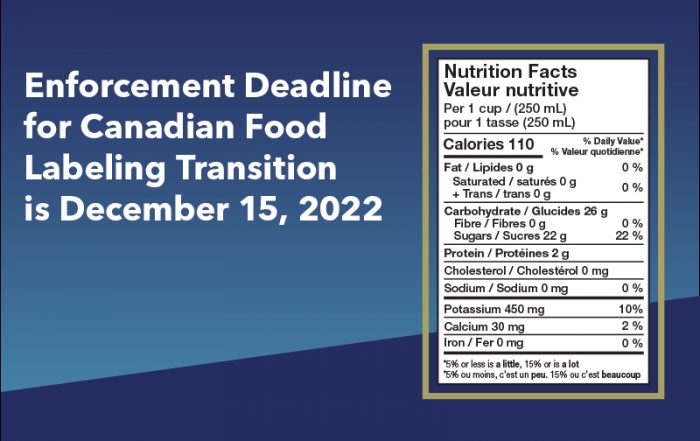

Know the Regulations

There are regulatory mandates that plant-based protein manufacturers are required to understand and follow. For instance:

“Subsection 5(1) of the Food and Drugs Act states that no person shall label, package, treat, process, sell or advertise any food in a manner that is false, misleading, or deceptive or is likely to create an erroneous impression regarding its character, value, quantity, composition, merit, or safety.”

In short, manufacturers are required fully educate themselves and their employees on the current available knowledge about the plant-based ingredient that they plan to use in their products, as well ensuring that their consumer-prepackaged food label provide sufficient transparency regarding all actual and potential hazards associated with their products.

How MCS Associates supports plant-based food manufacturers

There is no doubt that plant-based proteins are currently one of the better available substitutions for animal-based choices. The challenge for food business owners however is keeping abreast of new and evolving scientific studies that not only offer new insights on opportunities but also help to address uncertainties regarding food manufacturing safety. This can help to ensure that consumers are provided with up-to-date information for making informed decisions when choosing their plant-based protein source.

Our team at MCS Associates support food safety and quality requirements through facility audits, microbial risk assessments (Hazard Analysis Critical Control Points (HACCP)). Our affiliated laboratory can further support brands through routine analysis of protein quality in plant-based products, and chemical testing such as heavy metals, mycotoxin, and pesticides.

Can we help? Contact Us.

Contact our food safety experts at enquiries@mcs-associates.com to support your food safety requirements.