A Preventive Control Plan (PCP) is required under the Safe Food for Canadian Regulations [SFCR] for food manufacturers and importers. At its core, the purpose of a well written PCP is to protect consumers from food-related illnesses and injury.

The Canadian Food Inspection Agency (CFIA) defines a PCP as a written plan outlining the measures and actions taken to ensure “that food is safe for the consumer, is fit for human consumption, and conforms to safety and labelling requirements as prescribed by all applicable Canadian food legislation.” The written document outlines:

- activities taking place at your facility that can pose potential hazards and risks to food products,

- demonstrating how they are monitored,

- corrective actions if required, and

- verification procedures to ensure that preventive controls are in fact preventing, eliminating, and effectively controlling the identified hazards.

Elements of a Plan

Even though the content depends on activities you conduct at your facility, there are two main elements to developing your written plan.

First, Technical knowledge of how a product is made. This includes understanding the technology and equipment used in the facility, the practical aspects of food operations and the process flow of the facility.

Secondly, Scientific knowledge of food safety. This includes the applied aspects of food microbiology, chemistry and extraneous material in food, Hazard Analysis Critical Control Point (HACCP) principles and techniques.

Identifying the hazards

The food business is probably one of toughest businesses to be in given the many risks to deal with. Risk levels can vary depending the type of business you are operating. For instance, extreme high-risk foods such as meats and fish will require more greater levels of preventive control than perhaps a tea importer. Developing a PCP requires actively looking for where the hazards and risks are, assessing those risks against the chance of something happening balanced against the impact, apply risk controls and providing evidence how these risks are mitigated. Hazards can be broken down into three specific components, Biological, Chemical, and Physical.

Biological Hazards are potential sources for transmission and growth of microorganisms such as bacteria, viruses, parasites, mold, and fungi. It is imperative that effective preventive controls are in place for food products remain biologically safe all the way to the consumer. Sources can include incoming ingredients, cross contamination during processing storage; surfaces, utensils, and equipment that encounter food or create the potential for allergen cross-contact and cross-contamination; and from pests such as insects and rodents, transmission from water, air, and through employees.

Chemical Hazards can include those that are used during processing (i.e. food additives and agricultural chemicals) or naturally occurring by-products from processing (i.e. mycotoxins, nitrosamines, chloramines). Other non-food related chemical sources may include cleaning agents, oils, and lubricants, oil, and gasoline.

Physical Hazards can come from anywhere making their way into food products. Some examples include dirt or stones, metals, glass, and wood (i.e. from milling or grinding, packaging materials, wooden pallets), or from poor handling practices.

Critical Control Points

For manufacturers, any hazard that is not prevented using Preventive Controls (PC) is considered a Critical Control Point (CCP). The CCP outlines any steps in the manufacturing process that can affect product safety by potentially creating biological, chemical, or physical hazards. The PCP also includes steps to address potential problems should they arise. For instance, if your product requires cooking as a step, the critical control point will document how the minimum cooking temperature is monitored. If there is a problem during the cooking process, what immediate corrective action is to be taken to resolve the issue, identify the root cause and to prevent recurrence. The issue must be documented in physical or digital form for audit purposes. Prior to closing out the issues, the effectiveness of the corrective action must be verified that it is working with the evidence of it documented.

Successful identification and implementation of CCP(s) throughout the food manufacturing process encompasses seven control measures ensuring the safety of food as it flows through an establishment. These include:

- Conducting a Hazardous Analysis

- Determining Critical Control Points (CCP’s)

- Establishing Critical Limits

- Establishing Monitoring Procedures

- Establishing Corrective Actions

- Establishing verification procedures

- Establishing record-keeping and documentation procedures

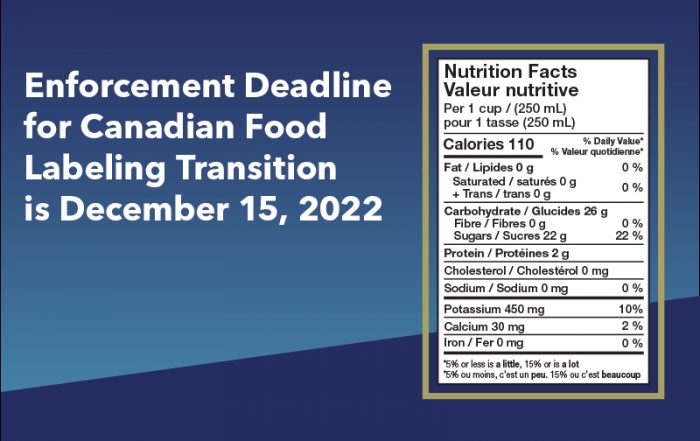

Labeling

Proper product labeling serves two purposes. First to protect consumers by highlighting ingredients that may pose a health risk such as allergens, and secondly to help them differentiate between individual foods and brands to find what they are looking for and avoid what they do not want. Labeling components include where the product is grown or processed. If grown, is the product conventionally grown or does it have characteristics such as being Certified Organic or Non-GMO. If the product is processed, is it sold raw, dried, flavoured, or roasted. Risk factors include information such gluten-, sugar- or dairy-free for the benefit of consumers suffering from allergies. Accurate product labeling is a critical component during product development or product formulation, and it get the support of an outside specialist if you do not have someone internally with the required skills and knowledge.

Where applicable, food grades on labels equally play an important role in communicating product quality and consistency not only for consumers but also for the food importers and manufacturers such marketing, to establish prices, standardize quality benchmark for provincial and international trade and protection against fraud or adulteration. Grades communicate to consumers the nature of the product as to its “flavours, aroma, texture, colour, moisture, size, maturity, firmness, shape, cleanliness, density, clarity, fat content, condition of the food, as well as different types of defects”. Grades are applied to meat and poultry, fish and seafood, fresh and processed fruits and vegetables, shell eggs, dairy, honey, and maple.

Food grades are regulated under Safe Food for Canadians Act (SFCA) and the Safe Food for Canadians Regulations (SFCR). To declare a grade name on products, importers and manufacturers must be license holders and apply for authorization from SFCR by meeting several conditions.

Maintaining your PCP

The food industry is very dynamic and there will be many instances that will prompt your PCP to be updated or reassessed. Some examples include the introduction of new products or product lines, product formulation and ingredient changes, new or revised production steps, new equipment introduction, as well changes to regulatory requirements, address consumer complaints and issue a product should the need arise.

This requires having experienced knowledgeable management and well-trained employees who can identify hazards and to solve issues.

Developing a written plan can be overwhelming and should is a team effort that is led by key person(s) at all applicable levels. Whether you are an importer or manufacturer, a specialized consultant like MCS Associates can help lead the way or close knowledge gap by evaluating your food production environment, your quality assurance and inspection procedures and developing and helping implement your food safety plan.